Innovative Integrated Drive Axle

Electric drive axles are used both as the primary drive for pure electric vehicles and as secondary drive axles for all-wheel drive electric vehicles and hybrid and Plug-In hybrid vehicles (so-called P4 hybrids). The goals in the development of electric drive axles are prioritized differently depending on the vehicle segment and market segment, in each case costs, comfort (acoustics), weight, efficiency and installation space are included. In particular, the attributes of efficiency and weight are in the focus of developments with regard to the range of an electric or Plug-In-hybrid vehicle. With focus on the concentric arrangement of rotor and output shafts, use of a solid rotor shaft, avoidance or compensation of transverse and longitudinal loads and a compact and lightweight design, a new structure of an electric drive axle was invented at pi³ GmbH.

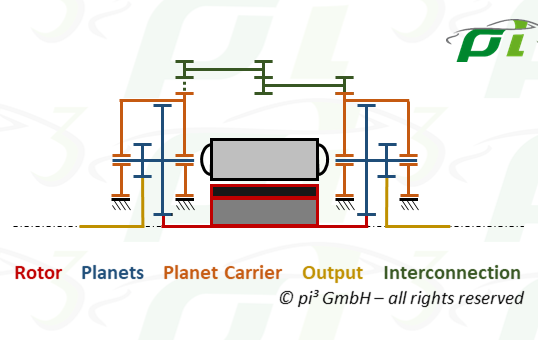

The innovative integrated drive axle consists of a propulsion unit, in particular an electrical machine, the rotor of which drives planetary gear sets on both sides, whereby these are designed as pure spur planetary gears. The two planetary carriers to the right and left of the electric machine are functionally connected to one another through a mechanical coupling, implemented for example by gears and shafts, so that their rotational movements have different directions. The planet carriers each carry an integer number of gear pairs (planets) which are connected by an axle which rotates in the planet carrier. The planets arranged on the side of the electrical machine mesh with the sun gears of the rotor or the rotor or input shaft of the propulsion unit. The other planets mesh with the sun gears on the output shafts on both sides, which are connected to the wheels via side shafts.

The innovative integrated drive axle is very compact and enables the use of an electric machine with a solid shaft, with the output shafts sharing the rotation axes together with the rotor shaft of the drive unit. The structure enables the speed compensation between the two output shafts, for example when cornering. By adding for instance a brake to the mechanical coupling, for example on the planetary carriers or their connecting elements, the differential function of the innovative integrated drive axle presented here can be blocked. A separable coupling can also be added to the mechanical coupling in order to separate the drive unit from the output shafts. The easiest way would be to use a slider gear.

By doubling the power transmission elements, in addition to the more compact design, there is also lower component loads and probably improved noise behavior compared to known solutions. Improvements can also be expected in terms of efficiency at higher loads, since there are hardly any bending loads and the sliding components in the running gears can therefore be optimized.

The innovative integrated drive axle is particularly suitable for electro mobility in a wide variety of vehicle segments and applications. The compact design enables use on both front and rear axles. Together with the scalability through the use of further pairs of planet gears, for example, a wide range of applications or power classes can be covered with a basic design.